Equipment Management | Huaxia Jianlong Organizes a Tool Positioning Management Improvement Campaign with the Theme of "Return to Designated Position After Use, Retrieve Instantly When Needed"

To further enhance on-site management and consolidate the foundation for lean production, from August 1 to September 5, 2025, a tool positioning management improvement campaign was launched among all subsidiaries of Huaxia Jianlong with the theme of "Return to Designated Position After Use · Retrieve Instantly When Needed." This campaign aimed at standardization, visualization, and efficiency, systematically advancing the standardized management of warehouses and toolboxes. It encompassed four stages: training, inspection, rectification, and evaluation, to comprehensively enhance on-site management capabilities.

Training First, Unifying Standards

From August 1 to 5, the company conducted specialized training sessions to systematically explain the implementation standards, steps, and common pitfalls of tool positioning management. It shared outstanding industry cases and clarified unified norms for tool cabinet management, ensuring that each subsidiary had a clear basis and standard for implementation. The training adopted a blended approach, combining online and offline methods, covering all relevant personnel across positions, and laying a solid theoretical foundation for subsequent practice.

On-Site Inspection, Precise Diagnosis

From August 6 to 10, specialized teams composed of equipment management personnel from each subsidiary conducted comprehensive and detailed inspections of warehouses and toolboxes in workshops. By systematically identifying issues in tool placement, labeling, maintenance, and other aspects, they formulated detailed diagnostic reports and developed targeted improvement plans, specifying responsible areas and teams to guide precise rectification efforts.

Full Participation in Rectification Yields Immediate Results

From August 11 to 25, each workshop and team actively implemented rectification tasks, comprehensively advancing tool positioning optimization and 6S management in accordance with improvement plans. All operators, team leaders, and other personnel participated, implementing a series of measures such as categorizing, positioning, and clearly labeling tools to improve tool management. Tools were neatly arranged on-site, with clear labels, and a scientific and reasonable spatial layout. The time required to retrieve tools was significantly reduced, and the rates of tool loss and damage were effectively lowered, achieving an efficient state of "visual management and instant retrieval."

Acceptance Inspection and Evaluation, Promotion of Results

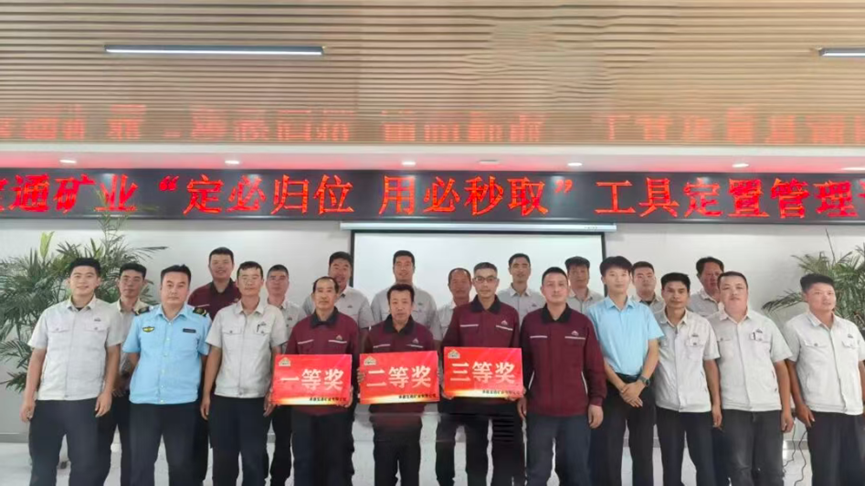

From August 26 to 30, each subsidiary organized specialized inspection teams to comprehensively evaluate rectification results through on-site inspections and benchmarking against outcomes. The inspection process not only focused on on-site improvements but also emphasized mechanism construction and standard implementation, ensuring that "return to designated position after use, retrieve instantly when needed" became a normalized management requirement. Additionally, evaluations were conducted to recognize outstanding organizations and teams, further stimulating enthusiasm for continuous improvement among all personnel.

This campaign represents an important practice in the company's pursuit of refined management. Through systematic training, diagnosis, rectification, and acceptance, it enhanced on-site management standardization and efficiency, and strengthened employees' awareness of norms and execution. The company will take this opportunity to continue advancing tool positioning management as a long-term mechanism, ensuring the practical implementation of the above-said principles and providing solid support for refined management to drive the high-quality development of the enterprise.